SSI- Screens - Trash Rakes - Service

SSI can design and build any product for your intake systems including, Traveling Water Screens, Bar Racks, Trash Rakes, Stop Logs, and Fish Handling Screens that are 316b compliant.

Wednesday, July 17, 2013

Wednesday, November 28, 2012

When it's busy season in business

During the busy season of any company you have to focus on a few key issues. We at SSI strive to focus on production, delivery and service! We're proud to say we have been able to complete yet another successful install.

Many customers who do not work closely with their intake want to know the purpose of this huge piece of equipment in their well. Traveling Water Screens are among a plant's first lines of defense from the debris in the water they draw in, and more recently they have begun to protect the environment from the plant or mill. It filters debris of varying sizes. If you have large debris you'll want to go with something like a trash rake as your first line of defense. But for grass and other manageable debris you want a screen. The beauty of a traveling water screen is that it will rotate and self-clean so you can continue to draw in water at the same rate without clogging of the baskets.

We at Screening Systems International work to custom design a screen to the individual intake well. Like anything else in business, you want your screen to fit your needs and be able to withstand the unique problems. We met this challenge by sending a team of technical designers down to the intake site to examine and measure the well. Once this is done we take external factors into account, such as the water. If it is salt or brackish water we generally recommend using 316 stainless steel frames but there are a number of options. Once the customer has let us know what materials and metals they would like to move ahead with we work on designing, drawing and getting an estimate together.

Everything up to this point is very important but a key factor to SSI's success is our production team. Our shop has required stop points all along the building process so we can ensure that everything going out of our shop meets not only the customer's custom design but our standards of excellence as well. If you are not proud of what you produce, you shouldn't be producing it!

Meeting delivery deadlines can be difficult when your shop is slammed but its something that is key to good customer relations. If there is a hold up on an order we always call the customer to confirm their needs and discuss the issue.

SSI's service crew is top notch! We have some of the most experienced crews who know what they are doing, do it quickly and done right. There is nothing worse than a huge screen that is just slightly tilted or lose. It can become a very costly problem in the long term. That is why our service teams check and double check every installation. Their years of experience and training ensure that each screen is installed right!

Labels:

Fish Handling Screens,

Intake Screen,

Screening Systems International,

SSI,

Trash Rakes,

Traveling Water Screens,

Water Intake Products,

Water Intake Systems,

Water Intake Well

Location:

Slaughter, LA, USA

Wednesday, October 24, 2012

SSI's traveling water screen installation team

SSI provides plants with every intake product they require and then sends out a service crew that has been working with intake systems for an average of 8 years! They can get the job done quickly and correctly! This helps insure the safety and life expectancy of the intake equipment.

When entrusting a service crew with your intake well and water intake products there are some concerns you need to address. You need someone who has experience in a very specific field of underwater inspections and water intake solutions. SSI Service Crews have experienced and professional Divers that utilize remote underwater video inspection to help troubleshoot problems with your intake, and to avoid dis-assembly of equipment if possible. And our passion is the delivery of high-performance, efficient and reliable solutions for power and municipal water facilities.

Our

well trained staff is dedicated to delivering the best solutions for

our customers. SSI is constantly looking for new and innovative

solutions that will satisfy our customers needs. We have experienced and

dedicated professionals that are here for all of your requirements. Our

draftsmen are well versed in both 2D and 3D applications. All of our

equipment and software is up to date and current. This allows us to be

years ahead of the competition.

Tuesday, September 25, 2012

Business as usual is changing!

SSI is breaking into a new phase of "business as usual." We're excited

to be growing and developing. We've expanded our technology and continue to learn how to move our company forward! Thanks to Dreamforce this year we were able to discover new ways to break into emerging markets via marketing and web development. This weekend SSI is proud to be sending our team to Weftec, the largest annual water quality conference and exhibition. We hope to contribute to making water intake systems more "fish friendly." We look to do this through the implementation of a Fish Handling Screen, in place of similar intake screens.

In addition to Dreamforce, a CRM conference, and Weftec, the water quality conference, we will be headed back to Power Gen! Our hope here is to expand our reach. It is always important for companies to stay on the cutting edge of industry. That being the case we want to meet with customers, reps and experts about the power industry. SSI has expanded our line of intake products which should provide for an exciting conference this year in Orlando.

Come visit us at our job fair and see the progress we've made!

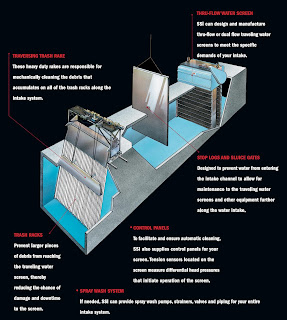

See a snap shot of what SSI can provide your water intake system.

Visit Us at www.screeningsystems.com

In addition to Dreamforce, a CRM conference, and Weftec, the water quality conference, we will be headed back to Power Gen! Our hope here is to expand our reach. It is always important for companies to stay on the cutting edge of industry. That being the case we want to meet with customers, reps and experts about the power industry. SSI has expanded our line of intake products which should provide for an exciting conference this year in Orlando.

Come visit us at our job fair and see the progress we've made!

See a snap shot of what SSI can provide your water intake system.

Visit Us at www.screeningsystems.com

Labels:

Dreamforce,

Fish Handling Screens,

Intake Screen,

Power Gen,

Screening Systems International,

SSI,

Thru-flow Screens,

Traveling Water Screens,

Water Intake Products,

Water Intake Systems,

Weftec

Location:

Slaughter, LA, USA

Thursday, September 6, 2012

SSI - Getting Social

Our SSI team has been working hard to find a way to stay social. Staying up to date in a social world can be difficult as a manufacturing company. We produce Water Intake Products, not the ideal social climate for twitter and the like.

However, working with traveling water screens, trash rakes and bar racks you come to find that there is a demand for these products at every water intake system. But to get your message out there you have to be a bit more creative. That's why SSI decided to follow the U.S. Environmental Protection Agency. While Water Intake Screens for nuclear, power and paper plants are not the number one focus of the EPA, the EPA has quickly become a focus of SSI's. Thanks to 316b, a section of the Clean Water Act, we have been able to expand our product line to include Fish Handling Screens for these intake systems. SSI is taking steps to help plants become more Eco-friendly to the bodies of water surrounding them. Once the final ruling comes down we will be able to assist plants with their new need to be up to code!

In the meantime, only a few plants are transferring over to the SSI "Fish-friendly" screens, because the ruling has been postponed until June 2013, and our focus can remain on dual-flow screens, thru-flow screens, trash rakes and other intake products. For those of you who do not know what these products are, dual-flow screens, like thru-flow screens filter some of the finer debris out of a plant's water intake systems'. This ensures that the plant doesn't take in the grass, mud, fish, leaves or other debris that could damage the intake. Some plant managers choose to have fine mesh paneling line the baskets of the screens in order to prevent smaller objects from getting into the intake, although that is less common because it can also cause a build up of debris. Meanwhile, trash rakes remove large debris such as fallen trees or limbs, and trash. SSI's most recent monorail overhead trash rake was able to easily lift 2,000 pounds in our test run. While this process needs to be manually operated it can still provide a quick and easy way to keep an intake system clear for the plant.

With such a niche market the SSI team has had to become more creative. We can look at our intake products as just that - intake equipment or we can chose to see the effect well made equipment can have on a plant and the surrounding environment and community. We chose to develop new products and perfect our existing products so that we will have something to talk about. We are developing not only for us but for our customers who have new demands but who still need quality.

ScreeningSystems.com

However, working with traveling water screens, trash rakes and bar racks you come to find that there is a demand for these products at every water intake system. But to get your message out there you have to be a bit more creative. That's why SSI decided to follow the U.S. Environmental Protection Agency. While Water Intake Screens for nuclear, power and paper plants are not the number one focus of the EPA, the EPA has quickly become a focus of SSI's. Thanks to 316b, a section of the Clean Water Act, we have been able to expand our product line to include Fish Handling Screens for these intake systems. SSI is taking steps to help plants become more Eco-friendly to the bodies of water surrounding them. Once the final ruling comes down we will be able to assist plants with their new need to be up to code!

In the meantime, only a few plants are transferring over to the SSI "Fish-friendly" screens, because the ruling has been postponed until June 2013, and our focus can remain on dual-flow screens, thru-flow screens, trash rakes and other intake products. For those of you who do not know what these products are, dual-flow screens, like thru-flow screens filter some of the finer debris out of a plant's water intake systems'. This ensures that the plant doesn't take in the grass, mud, fish, leaves or other debris that could damage the intake. Some plant managers choose to have fine mesh paneling line the baskets of the screens in order to prevent smaller objects from getting into the intake, although that is less common because it can also cause a build up of debris. Meanwhile, trash rakes remove large debris such as fallen trees or limbs, and trash. SSI's most recent monorail overhead trash rake was able to easily lift 2,000 pounds in our test run. While this process needs to be manually operated it can still provide a quick and easy way to keep an intake system clear for the plant.

With such a niche market the SSI team has had to become more creative. We can look at our intake products as just that - intake equipment or we can chose to see the effect well made equipment can have on a plant and the surrounding environment and community. We chose to develop new products and perfect our existing products so that we will have something to talk about. We are developing not only for us but for our customers who have new demands but who still need quality.

ScreeningSystems.com

Tuesday, September 4, 2012

SSI - Product Overview

Screening Systems International can manufacture any products you may need for your intake system.

SSI is able to stay on the breaking edge of intake system manufacturing

and design thanks to our dedicated design, manufacturing, sales, and

management teams.

We have designed and implemented a number of Fish Handling - 316b compliant traveling water screens, the most recent of which was installed at East River Generating Station. Although, the EPA has not come out with a final ruling on section 316b of the Clean Water Act, SSI has made being on the breaking edge of "fish friendly" screens a priority. Protecting the wild life around intake systems is the way of the future.

In addition to these SSI Fish Handling Traveling Water Screens, we have been active in manufacturing trash rakes for the larger debris that can block a plant's intake system all together. Our most recent Monorail Overhead Trash Rake was tested and able to life 2,000 pounds of debris, all which moving with ease and turning corners. This automated trash rake will increase efficiency and lower cost, in comparison to manual raking.

Some other intake products that SSI specializes in are our bar racks, bar screens, and stop logs. All of which are important aspects to any plant with a water intake system.

We have designed and implemented a number of Fish Handling - 316b compliant traveling water screens, the most recent of which was installed at East River Generating Station. Although, the EPA has not come out with a final ruling on section 316b of the Clean Water Act, SSI has made being on the breaking edge of "fish friendly" screens a priority. Protecting the wild life around intake systems is the way of the future.

In addition to these SSI Fish Handling Traveling Water Screens, we have been active in manufacturing trash rakes for the larger debris that can block a plant's intake system all together. Our most recent Monorail Overhead Trash Rake was tested and able to life 2,000 pounds of debris, all which moving with ease and turning corners. This automated trash rake will increase efficiency and lower cost, in comparison to manual raking.

Some other intake products that SSI specializes in are our bar racks, bar screens, and stop logs. All of which are important aspects to any plant with a water intake system.

Subscribe to:

Posts (Atom)